How to order steel wire rope

When requesting an offer or ordering steel wire rope (download order form), it is recommended to provide as much information as possible so that the manufacturer can accurately identify the product required by the customer.

Below you will find the essential information required to place an order.

1

SECTOR OF APPLICATION OF THE WIRE ROPE

(e.g. fishing – agriculture – hoisting – playgrounds – etc.)

The sector of application is the area in which the rope will perform its function.

Knowing the sector of application allows the manufacturer to make an initial wide selection from the numerous alternatives that fall within the company’s production range, narrowing the field in the direction of identifying the most suitable product to meet the customer’s needs.

2

USE OF THE ROPE

Knowledge of the specific use of the rope, that means the operations it will perform in the field, it is essential to define what characteristics the product should have, such as its degree of flexibility and strength.

3

ROPE DIAMETER IN MILLIMETRES

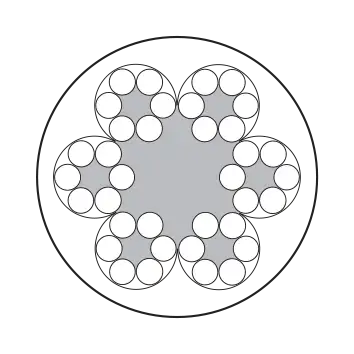

The rope diameter corresponds to the diameter of the circle circumscribed by the rope section.

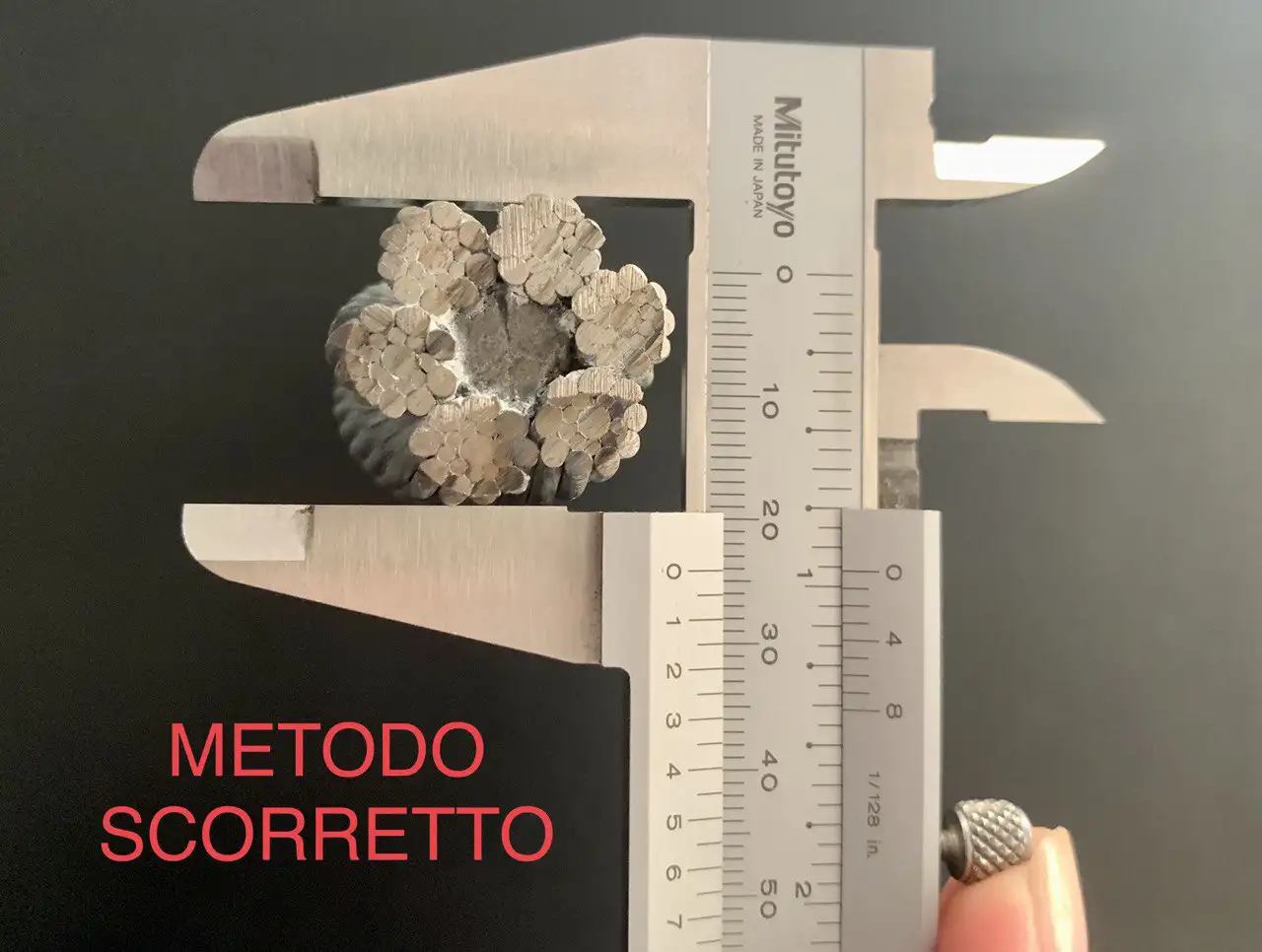

The diameter is measured using a caliper whose jaws must be positioned correctly on the rope, as shown in the pictures below.

4

ROPE CONSTRUCTION

(e.g. 1×7 – 1×19 – 6×7+AT – 6×7+AM etc.)

The construction describes the structure of the rope as measured from its straight section. It indicates the number and arrangement of wires, strands and core that make up the rope and is designated by numbers and abbreviations in letters.

5

ROPE CORE

(Fiber Core or Metal Core)

The CORE, as the term itself implies, is the central part of the rope that supports and stabilize the strands. It can be a Fiber Core (FC) if made of textile fiber yarns or PVC, or metallic (WSC / IWRC). The metallic core construction can be same as the strands one (WSC) or a different one (IWRC). The type of core, depending on the characteristics of the material composing them, contributes to determining the strength and flexibility of the rope.

6

GALVANIZATION

(Class A or Class B)

Our ropes are made exclusively from hot-dip galvanized steel wire.

Hot-dip galvanizing is a multi-stage process that gives the steel wire a protective zinc coating. The zinc coating that results from hot-dip galvanizing (https://en.wikipedia.org/wiki/Hot-dip_galvanization) forms a powerful barrier that protects the ropes against corrosion and prolongs their service life.

The main difference with other types of galvanization is that the zinc layer coating the steel is not a simple film. With this process, the zinc diffuses into the surface of the steel, forming a true iron-zinc alloy that clings tenaciously to the steel. Moreover, even in the event of any scratch, the protection of the wire is still guaranteed by the intervention of the cathodic action of the zinc, which, having a lower potential, oxidizes instead of the steel, preventing corrosion.

7

LUBRICATION

Some ropes need to be greased internally and/or externally with special grease. The grease has a protective and/or lubricating function, as it facilitates the sliding of the strands over each other and offers additional protection against oxidation and atmospheric agents, improving the performance of the rope and prolonging its life.

8

MARKS (fishing ropes )

This information relates exclusively to trawl fishing ropes, which are lowered into the sea in pairs and in parallel. The rope pair working together can be fitted with special signals marking their length at same regular intervals for both of them. The marks therefore provide a visible reference point that can facilitate the setting up of the ropes and the on-board operations connected to them.

The type of marks and the distance between them are therefore important information for the manufacturer that the customer must specify when ordering. This because the signals are placed during the roping process and cannot be added later if this phase has already been completed.

9

EACH COIL LENGTH (meters)

Ropes leave the production line in long rope batches and are then cut to length to be packed on roll or reel.

When ordering, it is necessary to specify the length required for each coil, the type of packaging and the total order quantity.

10

TYPE OF PACKAGING (roll, reel, other)

11

TOTAL COIL NUMBER and/or TOTAL ORDER QUANTITY (meters or kilos)

12

PARTICULAR REQUESTS, ADDITIONAL NOTES and/or IMAGES SHOWING THE PRODUCT DESIRED

Any additional information aimed at clarifying and specifying the characteristics and appearance of the required product (photographs, images, drawings, samples, etc.) is valuable for identifying the product.

Any special requests regarding the product (technical characteristics, packaging, samples, tests, documents, certificates, etc.) must be notified when placing the order.

To place an order, please download and fill in the order form (click to download).